Blog

News

Downloads

Links

FAQ

Guestbook

Forums

seacocks and thruhulls

REPLACING SEACOCKS AND THRUHULLS

Seacocks and thruhulls are parts of the boat which should be attached special attention. Everyone knows : advanced electrolysis, improper assembly, unsteady sealing can turn the boat into a pool, or even offer him a oneway ticket to the depths of the ocean ; apart from setting up a cone in the thruhull and pump, there is not much to do when you are far from a coast.

On the Amphitrite, there are 3 valves and thruhulls in each bathroom, one for emptying the kitchen sink, one for the admission of sea water, 2 or 3 for the engine, 2 or 3 for the pumps, and 2 for the log and sounder, and if there is a watermaker, generator, air conditioning or cooling unit with heat exchanger, much more. In total, this makes a lot of potential water inflows, it is imperative to monitor.

A seacock (= ball valve) must be replaced when it becomes hard to turn. For the thruhull is another thing. Here's what David MERLOT, former head of manufacturing at Wauquiez, to whom I spoke before operating :

In the shipyard Wauquiez

My advise is to keep the thruhulls. Why?

The material is sinter bronze, quality of alternator bearings ; in addition, it has a thickness of 5 mm and is included in the polyester (knurled diagonally).

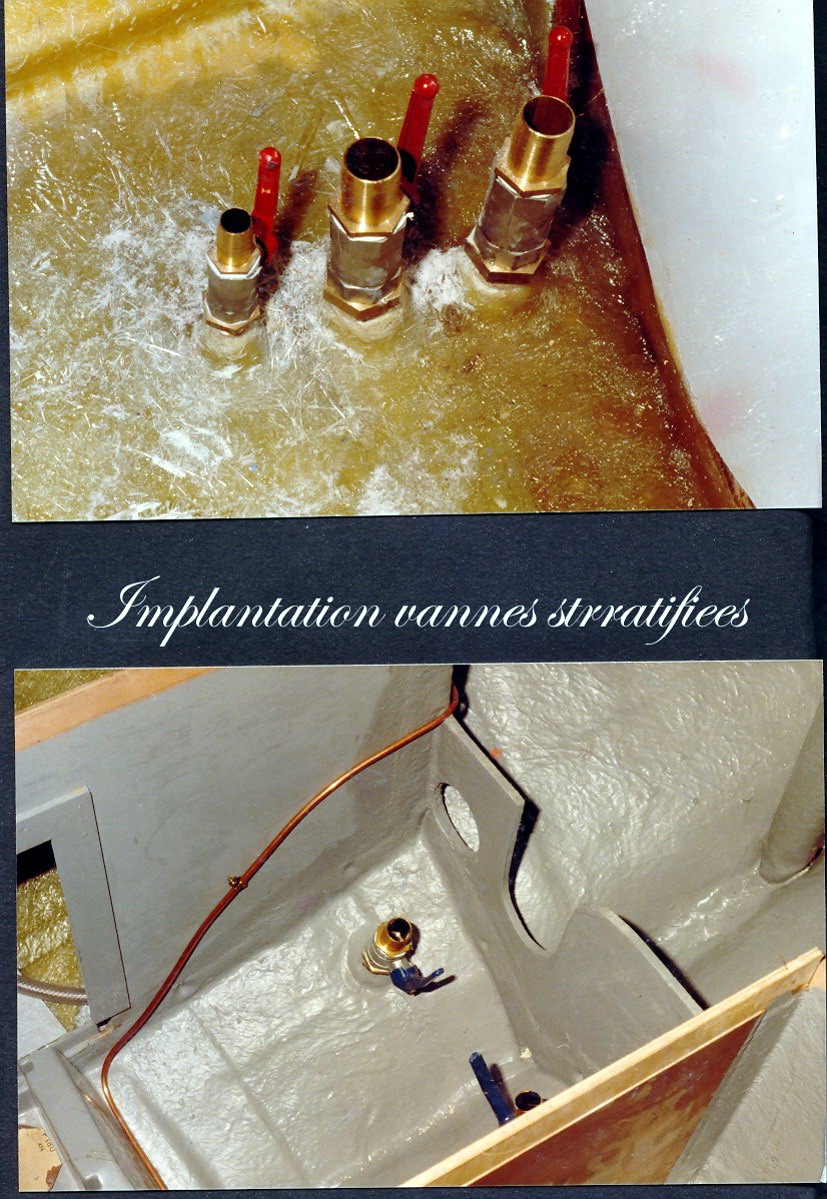

The thruhull was positioned in the mold immediately after casting the gelcoat and the hull was built around (thickness of 5 cm) ; by the withdrawal of the polyester material, it was blocked (see photo).

On the other hand, this mounting avoided to wear holes in the hull which kept all its seal ; but the thruhulls must be checked after taking down the seacock if there is no electrolysis ; to unscrew it no problem, no jamming ; the bronze must have a beautiful yellow color. Outside, when sanding, you can also judge the state of the thruhull (thickness and color).

You can screw directly into a seacock of stainless steel without corrosion problems. The nut is there to block the valve in a good position. Mounting with Teflon tape, you must be generous by turning, even better : screw and unscrew and set tape again.

Note : These tips are given only for thruhulls of origin, not those that were added during the installation of new equipments.

As I replaced five seacocks (toilet and lavatories) and as, the last I saw her, my boat was still floating, I might add that:

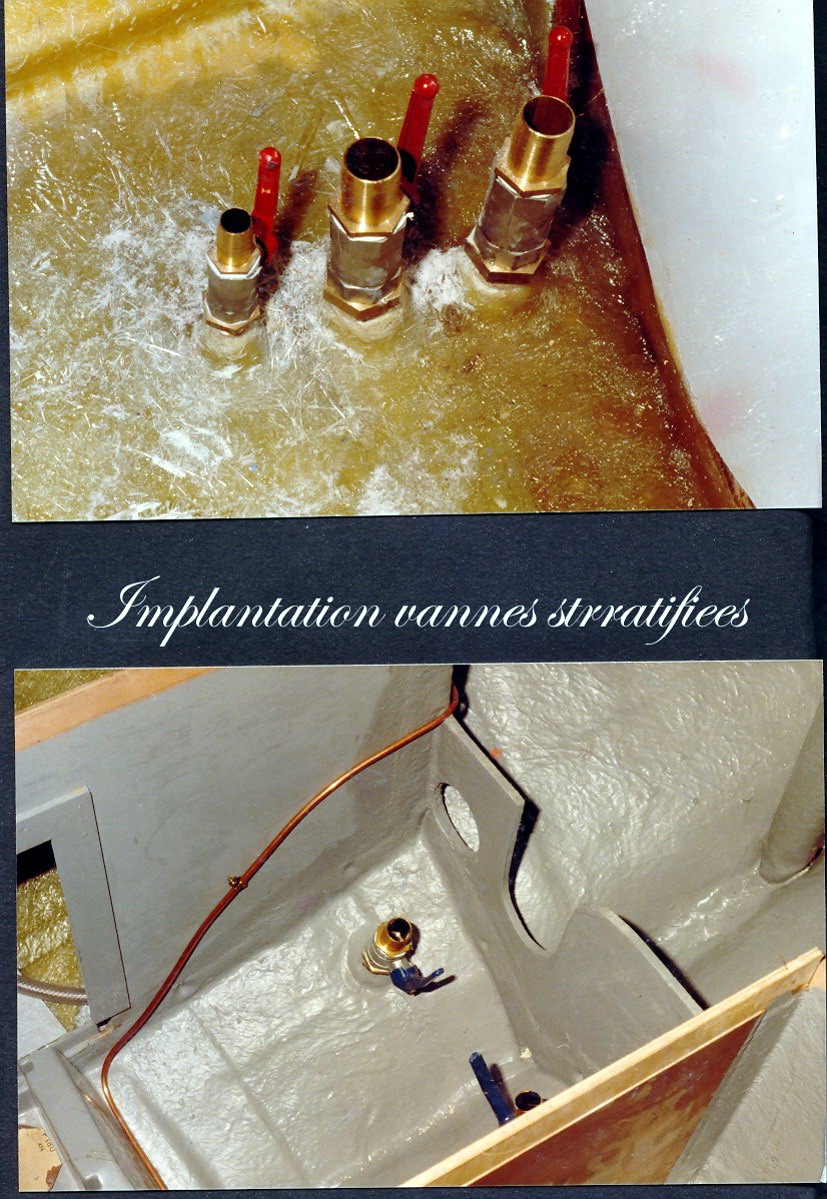

1. In the bow bathroom a valve resisted the dissambling ; i had to cut it away. In fact, it was a very difficult access and it was not possible to use a large tool.

2. After 28 years, the thruhulls show a beautiful yellow, no trace of electrolysis.

3. Between thruhull and seacock, I used Loctite 577, a product for sealing connection ; given the tightening of the 3 valves in a small space, it is not easy to apply sealing tape, but for pipe-to-hose adapters I used Teflon.

65.213.72.112/tds5/docs/577-FR.PDF

4. The dimensions of the valves (in inches) are : 1˝1/4 (toilet drain and sink), 3/4˝ (water inlet) ; adapters (of varying diameter) do not always stick with pipes, because, currently, it is used most often 1˝1/2. In Tunisia, it's simple : you let turn the parts you need.

5. In the aft bathroom rear (original !), the sink is not above the thru-hull : I got out of the valve with an elbow adapter.

6. I used both 316 stainless steel seacocks and brass seacocks to compare the lifetime of the 2 valve types.

See also: www.amphs.org / thread.php

Creation date : 21/05/2010 > 17:17

Last update : 26/12/2010 > 18:13

Category : Water and power

Page read 16187 times

Document generated in 0.17 second

.jpg)

_exposure.jpg)

_exposure.jpg)

_exposure.jpg)

_exposure.jpg)

_exposure.jpg)